There is no pre-established recipe in artisanal production: the beauty and the difficulty of this work lie precisely in understanding how the winemaking methods change every year and between the different lots of grapes. Every decision derives from tasting, accompanied by analysis. Tasting remains irreplaceable for grasping the complex balances that are the basis of a great wine.

Each step of the vinification and aging must be done with extreme care and skill but, in our opinion, it should affect the characteristics of the wine as little as possible. Wine personality remains unique if it essentially depends on the grape and the territory. However, this is possible only if an excellent job has been done first in the vineyard.

Only starting from optimal grapes (balanced, healthy, harvested at the best moment of ripening and selected) is it possible to carry out a cellar work that enhances the territorial characteristics, avoiding the use of chemical-physical interventions that alter their nature. Always with this in mind, we have chosen wine vessels and cellar tools among the most neutral ones, which affect the characteristics of the wine as little as possible, such as barrels that are not new.

The grapes are vinified in small separate lots, coming from micro-zones of vineyards with homogeneous characteristics. Each lot is thus followed with extreme care and in the most appropriate way for it. Some lots are mono-varietal. Others are the result of a careful study of field-blend, to obtain the unique synergies that develop from the co-fermentation of several varieties.

At the end, we analyze the wine to ensure the absence of any unwanted residue.

Some key elements:

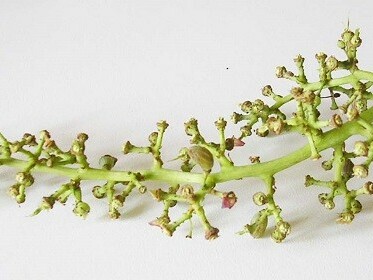

The grapes, after being harvested and selected, arrive in the winery (once called “tinaia” in Tuscany). To produce red wines, a destemmer-crusher is used, which removes the stalks and crushes the grapes very gently. The berries and the juice are moved to a fermentation tank. To produce white wines, after destemming, the grapes are pressed very softly.

The production of white wine is much more delicate than red, because it alters much more easily. The juice must be cleaned of all the vegetable remains. We do this by natural precipitation of the turbidities, leaving it in a cool place for one night. After that, the juice is transferred to a new tank.

Our job is to facilitate the alcoholic fermentation making sure that it takes place under the best possible conditions. It is important that it goes on slowly and in a regular way. We promote a high biodiversity of fermenting organisms in the first part of the proceedure, that promotes more complexity into the wine. When needed, the wine is briefly exposed to the air to give oxygen to the yeasts. Fermentation lasts an average of a week or so and ends naturally.

We vinify single lots of homogeneous vineyard parcels separately. Some lots include only one variety. Others come from the traditional practice of field-blends, fermenting several varieties together. The result is not the same: a synergistic effect develops in the co-fermentation which gives rise to unique aromas and flavours. Co-fermentation is possible for batches of grapes that have similar ripening times.

Maceration takes place simultaneously with the fermentation in red wine production. The grape skins, immersed in the juice, gradually yield colour, aromas, aromatic precursors and tannins. The duration of the maceration depends on the type of grape, of wine to be obtained (younger, less or more aged). It is not standard in artisanal production: it changes every year and for the different vineyard parcels.

The grape skins form a compact mass, called “the hat”, which floats on top of the fermenting wine. This hinders the desired extraction process and the skins could be subject to microbial contamination or other problems. Thus, it is necessary to gently stir the mass to avoid the formation of the hat. The frequency varies according to the grapes, the vintage and the wine types. We make fulling in the smaller vats, i.e. we stir with a long pole. Pump-overs are practiced in larger vats, with the use of a tube and a pump.

This marks the end of the maceration for red wines. The correct moment to do this is not easy to interpret for a high-quality artisan wine. It is decided with the gustatory evaluation of tannins, which can only be made by an experienced person who knows what they are doing. The practice is done by stopping the mixing of the tank and leaving the hat to form. The wine is slowly removed from the bottom of the tank. The pomaces are then pressed very gently to recover the part of quality wine that they still contain. They are then sent to the distillery for the production of grappa.

Malic acid is a grape component that can remain in the wine. It could be fermented by the lactic bacteria. Once this process was called the “second fermentation”. The acidic taste of the malic acid is very aggressive. Its content is highest in the unripe grape and decreases during the ripening, in a different way according to the climate. The high temperatures of the Mediterranean climate degrade it almost completely. So, it is absent or very low in ripe grapes. On the contrary, it is less degraded in cold climates, and the malolactic fermentation is very important to decrease the wine’s acidity. Moreover, that process adds some typical aromas.

Our white wines remain in the fermentation tank for aging on the lees, with frequent stirring. Aging gives more evolved aromas and the wines become more complex. Aging lasts around 4 months for our young wine L’Airone, around one year for Criseo, giving it a good longevity. The wine is clarified by natural decantation of the lees at low temperature.

Aging in wood is not possible for every wine: it is possible only with the right terroir and grapes, optimal balances, an appropriate vinification … The Bolgheri DOC production code establishes minimum maturation periods. Our red wines remain in the barrels from eight months to two years, depending on the types. We use small barrels (225 and 500 liters), not new. New barrels release strongly aromatic compounds, such as wood aroma and vanilla. We prefer the oak influence not to be too invasive.

Oak is a porous material and, with time, some of the wine tends to evaporate, lowering the level of wine in the vessel. This situation can then create a surface contact with air, subjecting the wine to irreversible alteration, oxidation. The casks are kept in the cooler and more humid area of the winery (called “bottaia” in Tuscany), in order to limit evaporation. However, each barrel must be continuously monitored and topped up if necessary.

The aging of red wines is traditionally done on the lees, with the remaining yeast from the fermentation. This practice has a positive influence on the body, stability and complexity of the wine. This process requires labor-intensive monitoring. The lees tend to precipitate out to the bottom of the barrel. So, the content of every single barrel must be stirred at least once a week. The wine must also be tasted periodically, to avoid reduction phenomena caused by the lees that could affect the wine taste. If we find them in time, we resolve them with a wine aeration.

We do some racking at the end of the aging to clarify the wine (it is not filtered). We stop stirring of the barrels in the last months. The lees settle on the bottom and we gently transfer the wine into another barrel. A wine could be racked 5-6 times or more, depending on its state. There is the possibility that a very small amount of sediment is present in the bottle: it is a sign of an artisanal wine.

Each barrel experiences its own evolution during maturation. Each barrel contains wines born in a vineyard parcel, with one or more varieties. These individual lots must then be combined with care, expertise and sensitivity to construct the definitive blend. The final blend rests some months in a tank, so that its constituent parts can marry naturally together. It is like a birth: it requires time, so that the individual parts can create something that is not simply the sum of them but the expression of a unique synergy.

Sulphites are produced naturally in wine, since a small part comes from the metabolic activity of the yeast. The introduction of sulphites in wine is due to its properties as an antimicrobial, antioxidant, and preservation agent. The amount is determined at bottling.

After bottling, we let the wine rest in the bottle, stored horizontally, for a period of three months to several years, depending on wine type. A shot period in the bottle allows the young wine to “recover” after the stress of bottling. During longer periods of ageing, transformative processes take place, with a softening of the tannins, tempering of acidity, and evolution of aromas, which complete the personality of the wine.

Insights

The new European wine labelling rules

11 December 2023

We’re certifing our wines as sustainable

27 June 2022

Stem or not stem vinification?

28 March 2022

2021, a remarkable vintage: about the harvest

16 October 2021

We present our vineyards 1: Campo Bianco

30 June 2021